MONDI - Extinguishing the KAMIR tower

Autonomous extinguishing system

STOP-FIRE-SAPFIR

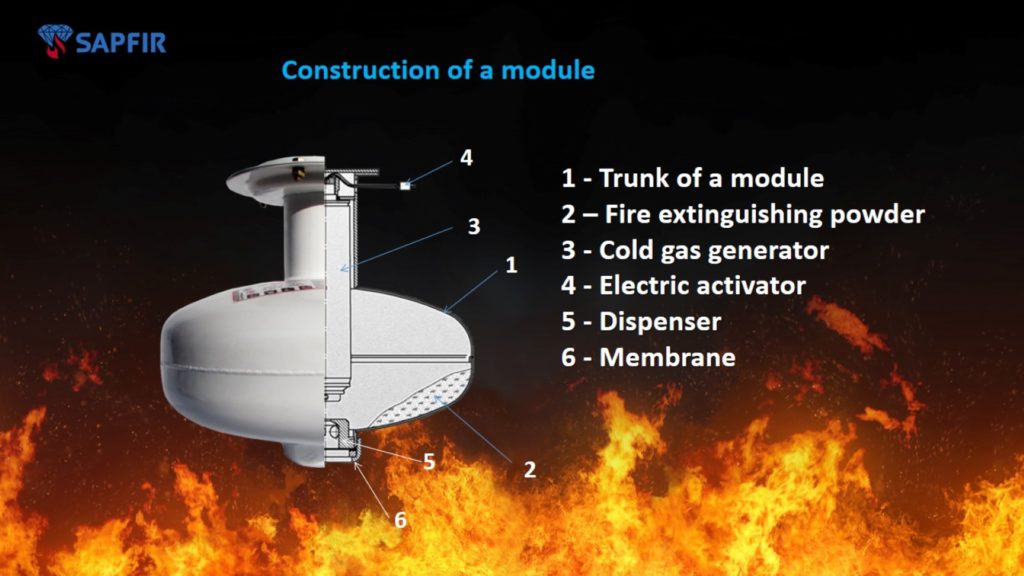

SAPFIR extinguishing systems are maintenance-free and pressure-free devices that have a guaranteed lifespan of 12 years. Specifically, if the extinguishing system is located on such a tall building, where it is exposed 24 hours a day to frost, wind, rain and high temperatures in the summer, it is necessary to physically check the functionality of the device once every 3 months. Whether there was any mechanical damage to the extinguishing modules, temperature sensors or cable lines. During the service check, each temperature sensor and each fire extinguishing module is checked separately. Even after the 12-year warranty has expired, regular service checks will be carried out. After each service check, the status = functionality of each extinguishing module will be recorded. If they are still functional after 12 years, they will be allowed to function in the KAMIR Tower extinguishing system for another 6 months.

On 23/10/2022 – a fully functional automatic extinguishing system of the Kamir tower was installed

The Sapfir autonomous extinguishing system consists of several separate extinguishing zones. Each extinguishing zone is composed of a TPS-01TC-73 temperature sensor + 1 or more MPH extinguishing modules.

The Kamir tower is a bit different from the Superbatch tower. Here the difference is in the installation of a large fire extinguisher which is placed on the side under the belt and ensures internal extinguishing of the upper and lower parts of the belt (extinguishing of the belt KA upper part – pipe) with the main extinguishing effect for extinguishing the largest pile of sawdust that permanently accumulates under the belt at the end of the conveyor .

Extinguishing zone No. 1 = Extinguishing cannon MPH-24T + 2x TPS-01TC-73 + 2x MPH-5T

The top photo shows the location of a large fire extinguisher MPH-24T with a capacity of 250 m3 of extinguishing, which is connected to a separate temperature sensor under the belt. It is designed to activate fire extinguishing in this space, but at the same time, another temperature sensor TPS-01TC-73 is connected in series, which is connected in series to two opposite fire extinguishing modules MPH-5T. These extinguishing modules are simultaneously activated together with the fire cannon if a fire occurs under the belt and their total combined extinguishing capacity is 450 m3!

Before installing the extinguishing modules, it was necessary to completely remove a continuous layer of sawdust with a shovel, which reached up to the upper edge of the beam where the central temperature sensor TPS-01TC-73 is located.

Therefore, the decision was made to change the external side location of the fire extinguisher to internal extinguishing. The force of the extinguishing pressure can break the continuous large pile of sawdust that was there, and at the same time, two fire extinguishing modules 2x MPH-5T placed opposite each other on the side panels will create an extinguishing wall (365° extinguishing) and close the debris shot inside, thus multiplying the extinguishing effect and at the same time reducing risk of explosion of burning particles from the tower down into the surroundings.

Zone No. 2 = Extinguishing module MPH-5T + sensor TPS-01TC-73

The picture shows the location of the MPH-5T extinguishing module with a connected temperature sensor TPS-01TC-73.

The capacity of this extinguishing system is 100 m3 and it starts automatically when the temperature exceeds 73°C for more than 10 seconds. If the main cylinder catches fire, a temperature of over 100°C will be generated here within a few seconds. If the temperature does not drop, automatic extinguishing will occur in this zone and thus eliminate the fire as soon as it starts. The effective extinguishing zone has a circle radius of 5m/365°.

Zone No. 3 = 2x Extinguishing module MPH-5T + sensor TPS-01TC-73

2 pieces of MPH-5T extinguishing modules with a central temperature sensor TPS-01TC-73 are placed opposite each other on the upper part between the two rollers of the conveyors. This is again a separate firefighting zone that is independent from other firefighting zones. If a bearing seizes and a fire occurs, the sensor is located in the middle between the two belts. This ensures the timely activation of extinguishing simultaneously of both MPH with a total capacity of 200 m3.

Zone no. 4 = 1x left small fire extinguisher MPH-10st + sensor TPS-01TC-73

Zone No. 5 = 1x on the right small fire extinguisher MPH-10st + sensor TPS-01TC-73

On the top left, there is 1 cannon + temperature sensor, also on the right is the mirrored location of the extinguishing system. Each side has a separate extinguishing system, it is related to the location of the covers of the upper part of the conveyor. In the second half, towards the end of the conveyor, there are temperature sensors on the left and right. If there was a fire below so intense that the flames would engulf the sawdust above the belt. There are 2 separate fire extinguishers for the entire length of the belt. Each cannon has an extinguishing capacity of 240 m3, which in combination makes a total extinguishing capacity of 480 m3. Each TPS-01TC-73 sensor has its own alarm line which is connected to the beacon + GSM module which, in the event of extinguishing, sends an alarm SMS message to a mobile phone of 6 numbers. Extinguishing zones 1-5 are generated in the sms message as belt extinguishing (belt extinguishing KA upper part – pipe). Zone No. 6 and No. 7 will be generated as extinguishing the top (extinguishing the pass KA upper part – tower).

Zone no. 6 = 1x left MPH-2.8T + MPH-065T + sensor TPS-01TC-73 extinguishing pass KA upper part – tower

Zone No. 7 = 1x to the right MPH-2.8T + MPH-065T + sensor TPS-01TC-73 extinguishing pass KA upper part – tower

These two extinguishing zones will be generated on the GSM module as Tower Up extinguishing. The GSM module allows alarms to be sent to two separate inputs. Therefore, zones No. 1 – 5 will be under one entrance, belt extinguishing (belt extinguishing KA upper part – pipe).

2x MPH-2.8T fire extinguishing modules are mounted on the top of the tower with fire extinguishing inwards between the bearings of the main belt = shaft. I have thoroughly physically inspected the entire tower, I am also attaching photos from the inside of the conveyor tower. Based on this thorough inspection, I proposed the correct placement of all fire extinguishing modules as well as temperature sensors that trigger fire extinguishing in critical zones. Specifically, there are two separate zones at the top of the tower. The left side contains 1x MPH-2.8T with extinguishing to the inside + MPH-065T with extinguishing of the outer shaft where there was a fire in the past. I moved the fire extinguisher MPH-065T module vertically up beyond the beam. This simplified the maintenance work, it was not necessary to cut a hole in the iron cover, and at the same time we used the open top and the ideal extinguishing method. The module does not interfere and has an ideal distance for 100% extinguishing. Both extinguishing modules are connected to the inside by the temperature sensor TPS-01TC-73, which is placed in such a way that it thermally covers the inner and outer parts, and thus if a fire starts outside or inside, there will be a maximum delay of 15-20 seconds.

The total internal extinguishing capacity of 2x MPH-2.8T is 130 m3.

During the installation of the extinguishing system, we dismantled the rubber covers on the shaft where there was a fire in the past. The entire interior space was filled with sawdust and fine compressed wood dust. This creates physical friction that eventually causes a fire. Therefore, at the daily meeting with the Mondi management, I drew attention to this and suggested not to put the rubber apron there. It acts as a stop behind which wood waste accumulates and this eventually results in a fire.

The attached photos map it all:

Neither the fire extinguishing modules nor the temperature sensor themselves consume any electricity. Energy. The extinguishing modules do not contain any internal pressure during the entire guaranteed lifetime of the extinguishing system = 12 years. Therefore, no pressure tests are necessary for their operation, and the powder itself does not harden even after 12 years in the extinguishing module.

The only way to check is a mechanical check to see if there has been manual damage to the extinguishing modules or the temperature sensor. Every 6 months, a physical check of the functionality of the cable lines (resistance check), magnetic check of the alarm line of the Temperature sensor + measurement of the Ohms of the cold gas generator in the extinguishing module is carried out. Every 6 months, a service check is carried out where the functionality of the entire extinguishing system is checked.

The extinguishing system was fully activated into automatic extinguishing mode.