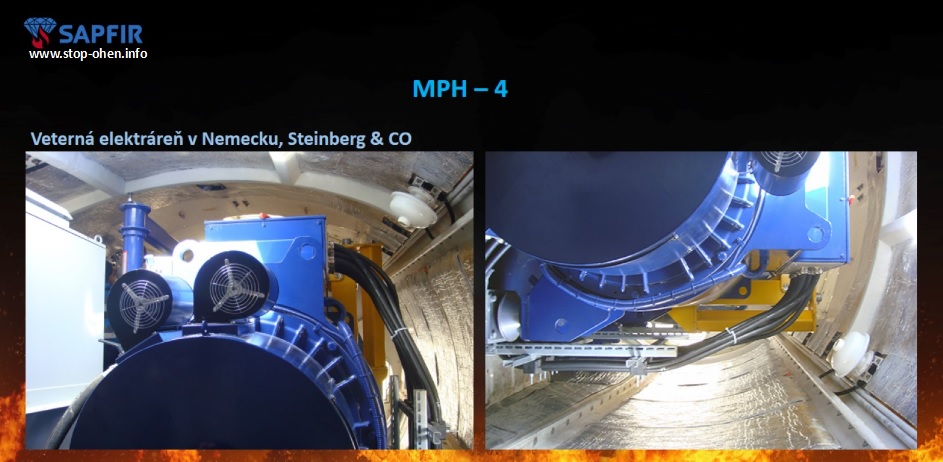

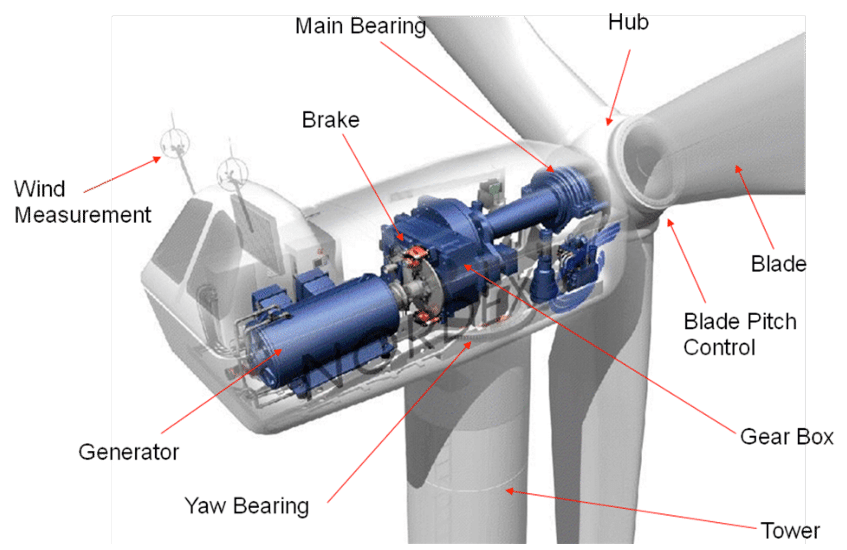

Construction of a wind power plant

Functionality and problems of the wind power plant:

The wind farm produces electricity by converting wind energy by rotating propellers. In a vehicle, an alternator is used to turn the vehicle’s engine. In this case, 3 blades are used to spin the generator, on which air currents (wind) are supported. That’s why wind farms are so high and with a large propeller span. The higher the height and the larger the propeller, the more electricity it produces from the wind.

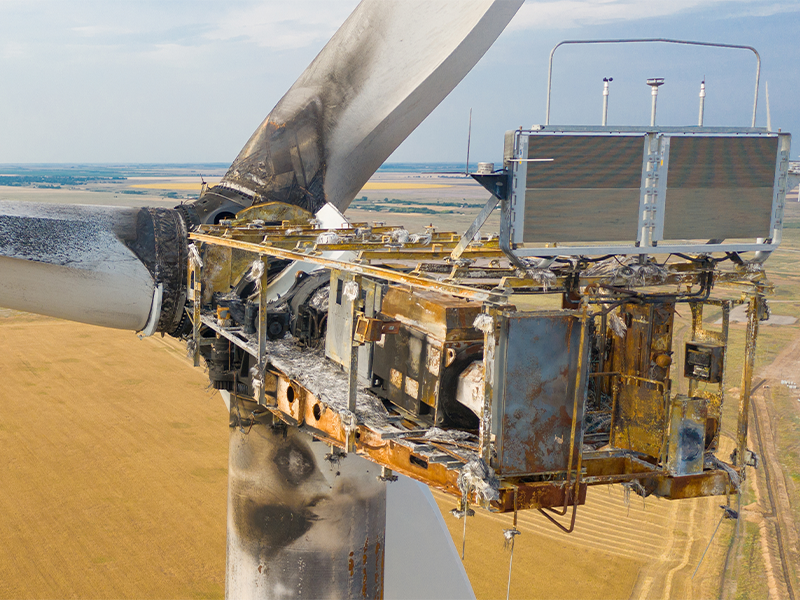

Disadvantage of the height and the size of a propeller:

Each wind farm must be equipped with brakes that slow down the speed of the generator. Like the engine in the vehicle, the electric generator has a maximum speed per minute. If the given speed is exceeded, the generator will be physically damaged and the propeller blades will break as well. To prevent this from happening, the brakes on the vehicle must brake the propeller speed. The stronger the wind, the higher the speed of the propeller / generator.

If a strong wind is blowing, then the brakes will lock and the propeller will stop rotating to prevent damage to the wind farm. But both on the vehicle and at such a power plant, brakes or electronics can fail. And as it is well known, both electronics and brakes start to burn from time to time. And for this case, an autonomous STOP-FIRE-SAPFIR powder extinguishing system was developed.

Autonomous extinguishing SAPFIR

Basic advantages of STOP-FIRE-SAPFIR powder extinguishing:

- Automatic extinguishing without the need for human intervention and 12 years guarantee of functionality.

- Extinguishes all types of fires (A, B, C, E), including electrical transformers up to 40,000 V without damage.

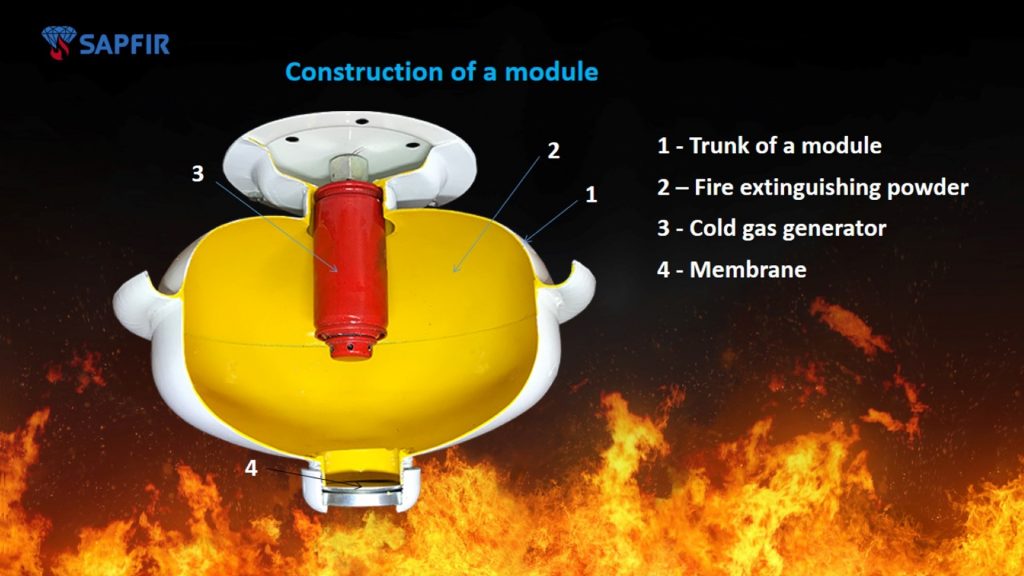

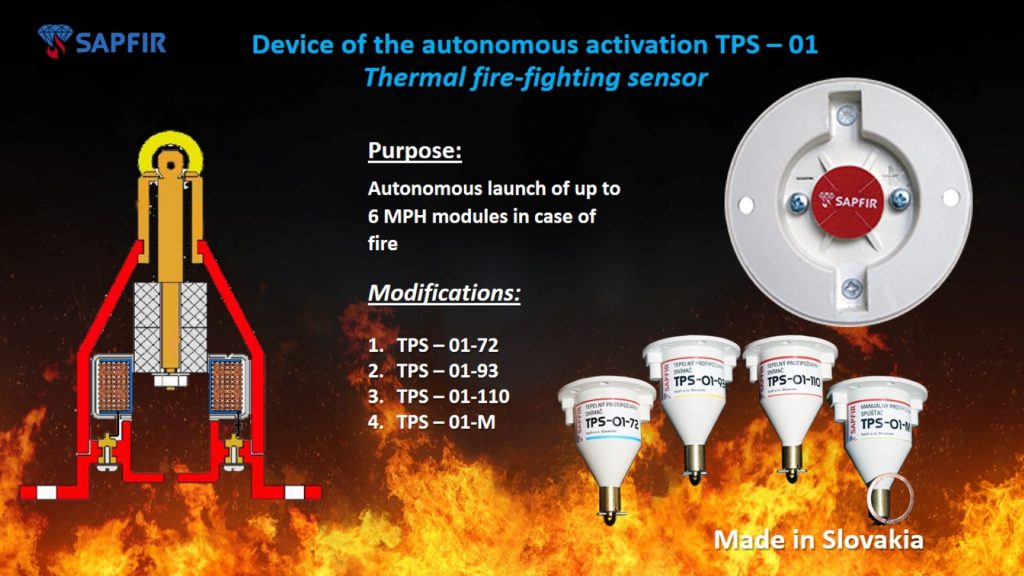

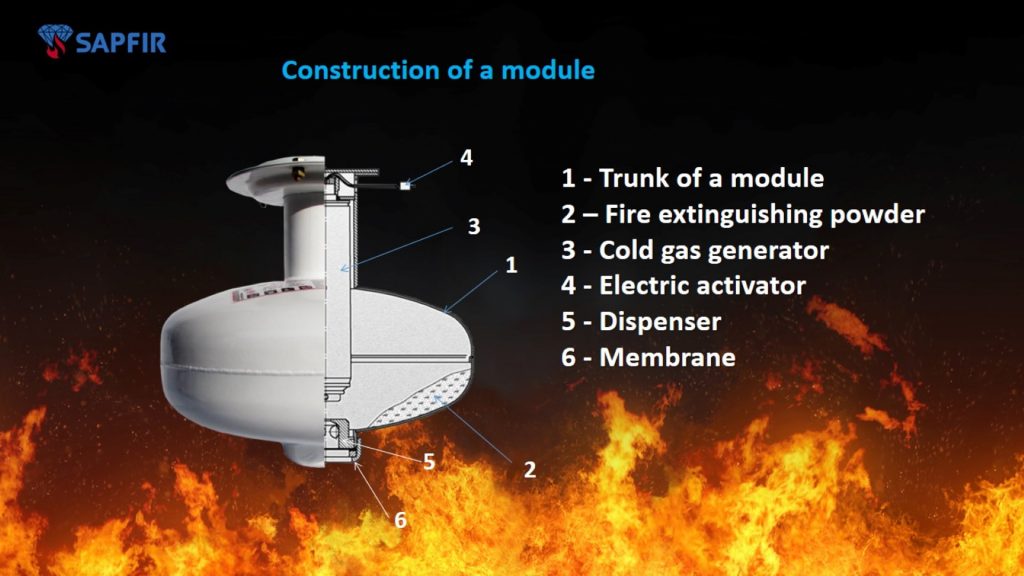

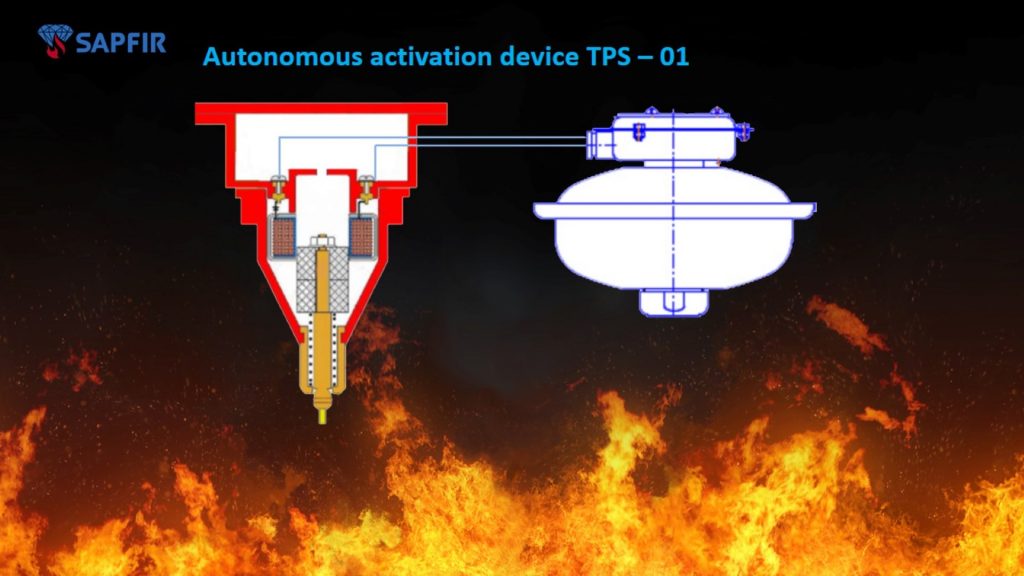

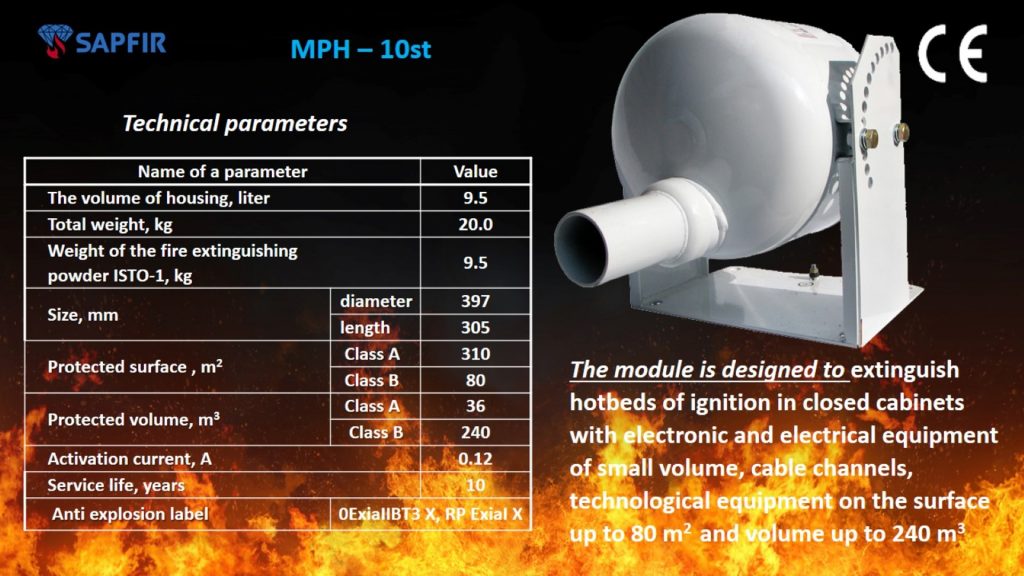

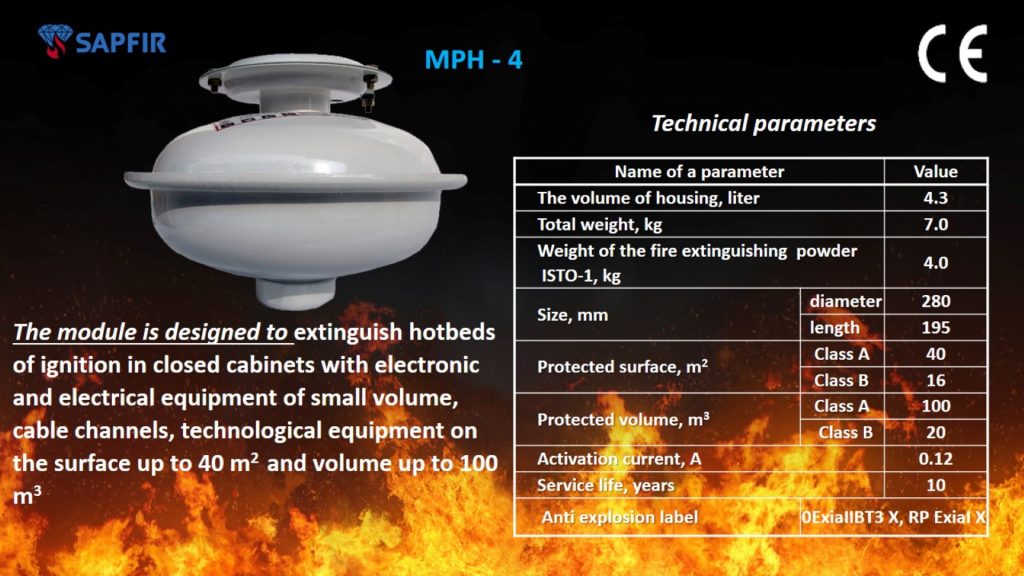

- The TPS temperature sensor is also an electric impulse generator which in case of fire sends electrical pulse of 0.5A to the fire extinguishing module MPH. It activates a cold gas generator inside the MPH, which creates a high pressure of cold gases (rocket engine) and these are mixed with ecological powder inside the fire extinguishing module. When the critical pressure is exceeded, automatic extinguishing occurs.

- The MPH extinguishing module does not contain any internal pressure until the extinguishing process has taken place. There is only powder and a cold gas generator inside. Therefore, the fire extinguishing system is maintenance-free for a guaranteed 12 years of system life. The extinguishing system is 100% passive and has zero power consumption.

- The operating temperature of the fire extinguishing system is in the range from -65 to + 125 °C, as it is a powder dry extinguisher that does not freeze, unlike water or foam extinguishing.

- The extinguishing system is highly efficient with low construction requirements and quick and easy installation.

- Investment costs for STOP-FIRE-SAPFIR extinguishing range from 30-50% of the price of competing gas, water or foam automatic systems. Beauty is in simplicity.