Rail plow = Plasser & Theurer SSP110SW

Rail plow = Plasser & Theurer SSP110SW Illustrative photos after the fire of a similar locomotive. This particular burned down completely.

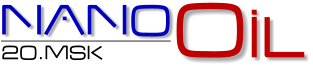

Design of SAPFIR LOCO extinguishing system

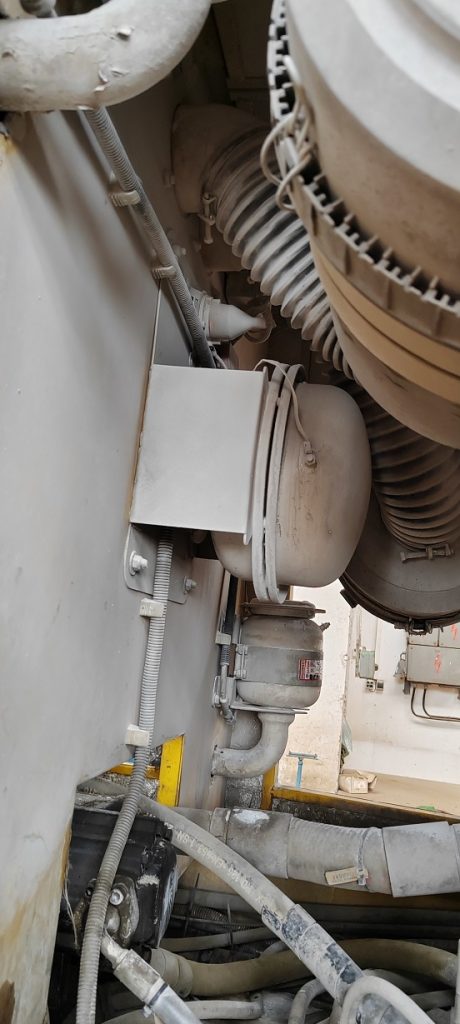

Inspection of the locomotive in the depot during the reconstruction after the fire. Year 2017 in the Czech Republic depot Lovosice

PROTOTYPE – SAPFIR LOCO has been specially developed for this particular type of track plow, as there are often fires in the engine compartment as well as on the axle transmissions. Every company that owns locomotives or rolling stock has experience with fire. In most cases, those fires end in total damage, as was the case with this locomotive. Its reconstruction and outage for a period of approximately 2 years cost TSS Grade approximately CZK 60 million. Therefore, we were asked to invent an autonomous extinguishing system that does not freeze in winter and works automatically even in summer when temperatures are high.

We designed an extinguishing system consisting of three extinguishing systems and three temperature sensors, as the original design was modified by the client only for the temperature sensor of the front gearbox. The engine is air-cooled and the estimated temperature in the engine compartment is around 100 °C. Therefore, for a period of half a year, we left the Temperature Sensor in the engine section physically blocked against automatic extinguishing. In the event of a fire, only an alarm would be triggered and the locomotive crew would manually initiate the fire extinguishment.

The test of the temperature course during the operation of the locomotive was successful during the summer heat. Even during half a year of operation, the temperature sensor (110 °C) was not activated by a false alarm. This means that even in the greatest heat during the summer, the temperature in the engine compartment does not exceed 110 °C.

At the first scheduled fire control service, the manual stop on the engine temperature sensor was removed and the engine fire extinguishing system was put into automatic operation.

You can see the first fire control service in the attached video. The automatic extinguishing mode was still manually blocked on the motor sensor.

08/302018 engine fire

Automatic engine extinguishing was activated during the transfer. The fire was automatically extinguished within a few seconds by two MPH-2.8T fire extinguishing modules. The crew stopped the locomotive, performed a small service and blew extinguishing powder away with air and continued driving. Subsequently, the next morning, the SAPFIR technician inspected the system with a subsequent order to replace the fire extinguishing modules for the engine. The locomotive then continued to order.

Inspection of the locomotive after the fire at the train station in Považská Bystrica

Replacement of fire extinguishing modules and system expansion

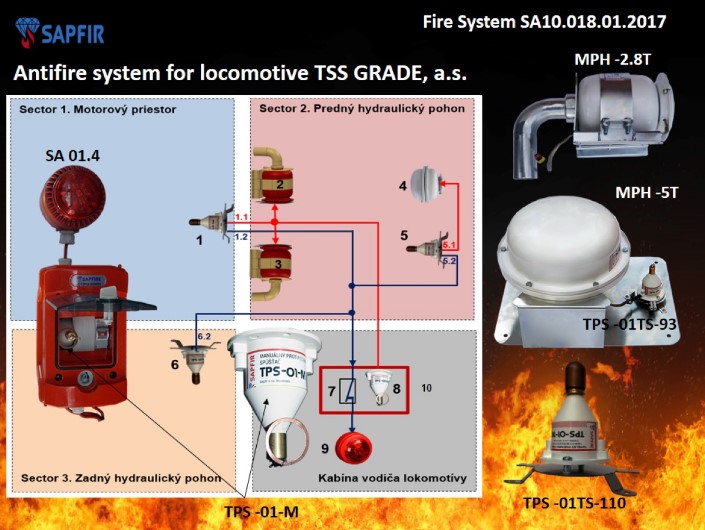

9/23/2018 engine extinguishing replacement

A service was performed on the border with Ukraine where the original temperature sensor TPS-01TC-110 was replaced by a newly developed prototype TPS-02-180, which we developed for another client, but it is also suitable for locomotives. In addition to two fire extinguishing modules for extinguishing the 2x MPH-2.8T engine, the system was supplemented by a fire extinguishing module to the existing temperature sensor above the front gearbox under the aggregate tank. In the event of a fire in the transmission’s hydraulic lines, the fire will be extinguished automatically within a few seconds, as in the case of an engine fire.

The system has definitely been extended to 3 separate extinguishing zones:

- Extinguishing the front gearbox (1x TPS-01TC-93 + 1x MPH-2,8T)

- Hydraulic pump extinguishing (APPS MPH-5T + TPS-01TC-93)

- Engine extinguishing (1x TPS-02-180 + 2x MPH-2,8T)

Service inspection 17.4.2023 fire extinguishing

The SAPFIR LOCO fire extinguishing system has a guaranteed functionality of 12 years if regular service checks are carried out. The fire extinguishing modules themselves and the temperature sensors as such have a minimum service life of 12 years without problems. However, on a machine such as a locomotive where some sensors are placed on the undercarriage as well as fire extinguishing modules are exposed to physical properties such as snow, ice, water, stones resulting in physical damage to the wiring or the very parts of the fire extinguishing systems. Therefore, it is necessary at least 1x in 6 months to carry out a comprehensive inspection of the entire system. This is a dirty and physically demanding job, but the service must be done thoroughly. To ensure 100% fire extinguishing functionality. With such a complete inspection, mechanical damage to the temperature sensor for extinguishing the gearbox is detected during the given service. As part of the warranty service, the sensor was replaced with a new one and the system was fully functional again.

2023-07-03 Depot screws replacement of fire extinguishing after fire