After the fire of the robotic line in the Hyundai car plant, there were millions lost in damages to the robots assembling cars and the subsequent outage of the production process. Existing fire extinguishing systems were unable to extinguish the fire in time and therefore there was consequential damage (water and electronics do not tolerate each other). Therefore, Hyundai’s headquarters in Korea sent its representatives to Slovakia to the SAPFIR manufacturer in Slovakia, in order to develop an autonomous fire extinguishing system that would not damage the electronics of robotic lines and also will not damage the health of people in production. The only extinguishing system that meets the requirements is the autonomous SAPFIR extinguishing system.

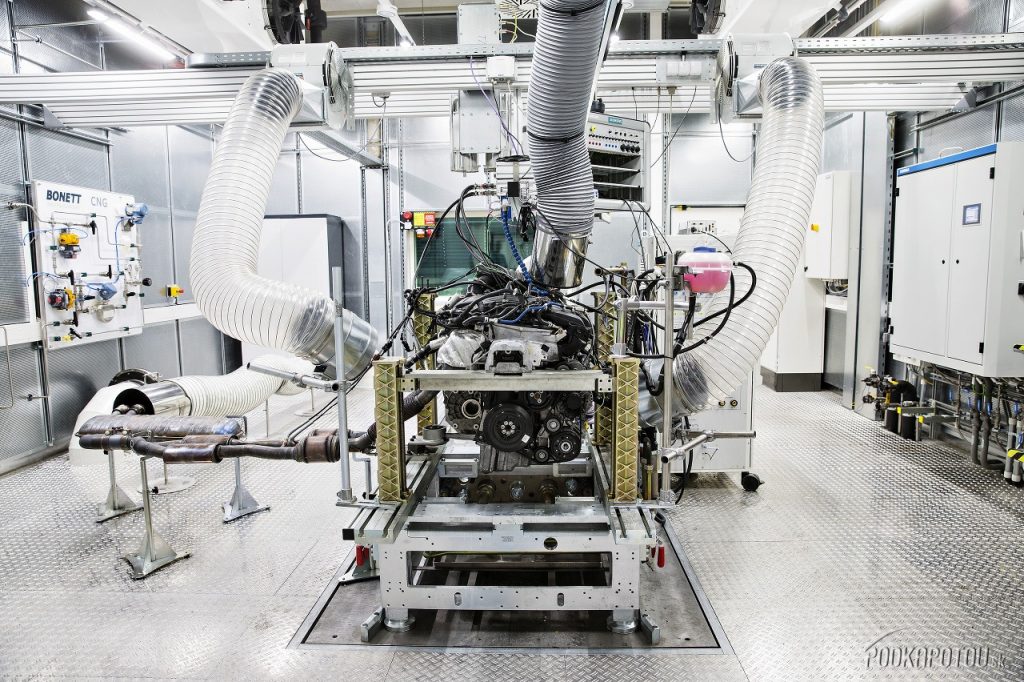

After an inspection of the car factory in the Czech Republic, a fire extinguishing system for robotic lines, hydraulic pumps, control electronics, cable tunnels and other production lines was subsequently designed.

The extinguishing of the robotic lines itself was assembled within 2 days during full operation.

In the subsequent stages, SAPFIR installed fire extinguishers without maintenance powder systems in the Czech car manufacturer and subsequently also in the Slovak Republic.

The difference between gas and powder extinguishing is in efficiency and temperature. Gas extinguishing is effective only in an enclosed space, where the gas must be pressurized into the room under high pressure and in a large volume. The larger the room, the more gas has to be pressurized there and the more expensive the technology. During the extinguishing with gas under the spray, a temperature of 200 – 300 °C is created. Extinguishing the gas itself is toxic and if there were people in the room, they would suffocate! Gas extinguishing is effective only in an enclosed space, for example, if it extinguishes a fire in an engine room (takes oxygen) and thus extinguishes the fire. However, if you open the door and get oxygen, the fire explodes like dynamite. This has happened in the past at one of the engine plants to develop and test engine life. Powder extinguishing is non-toxic and effective even in open spaces, extinguishing temperature is up to 10 ° C.

SAPFIR autonomous fire extinguishing systems are maintenance-free powder self-extinguishing technologies with a guaranteed service life of 12 years. They are designed to extinguish all types of fires (except molten metal) in any environment. Because they do not contain water (only organic powder) and do not have internal pressure, they are 100% maintenance-free. The fire extinguishing system itself consists of a TPS temperature sensor which is also an electric pulse generator connected to 1 or a maximum of 6 MPH fire extinguishing modules. Thus the system is absolutely passive = zero power consumption of energy. The extinguishing itself is fully automatic and works only on the thermo-mechanical principle. If the temperature in the room is higher than the set temperature sensor TPS, it switches on and generates electrical pulse of 0.5 A. This then activates the chemical generator of cold gases (rocket engine) inside the fire extinguishing module MPH. The whole process takes from 1 to a maximum of 10 seconds depending on the size of the fire extinguishing module. If sufficient pressure occurs inside the MPH, the splinters will open and the cold gas nano-powder itself will be fired. Therefore, SAPFIR extinguishing is simultaneously extinguishing the area in m2 and at the same time the volume in m3. Where, for example, the MPH-9 extinguishing module (extinguishing a petrol pump) extinguishes a fire on an area of 72 m2 but also at the same time a volume of 216 m3, which means that if the fire extinguishing module is placed on the ceiling at a maximum height of 10m. This will put out the fire, up to a height of 9 m! And also in the outdoor environment from – 65 to + 125 °C.

Here we come to the difference between water or foam extinguishing compared to SAPFIR powder extinguishing.

Water extinguishers, whether manual or automatic, are expensive and technically demanding to install. You must install water pipes and presses, you must have high-pressure pipes and a high-pressure pump with a tank of at least 5000 l of water. All this is extremely expensive and inefficient if the temperature drops below -5 °C. Then the water in the pipe freezes and tears the pipe (regular phenomenon). In addition, regular pressure tests of high pressure pipelines must be performed. It’s extremely expensive and…

SAPFIR fire extinguishing modules do not contain internal pressure. Therefore, they do not need pressure tests, they do not need pumps or water pipes. Installation is simple, fast and cheap. Inspections are performed every six months to physically check for manual damage to the system (impact of the VZV by the truck, etc.). Otherwise, control is fast and cheap.

Inside the fire extinguishing module there is only a cold gas generator (rocket engine) and the organic and 100% ecological powder itself. Therefore, fire extinguishing systems extinguish fires even at a maximum temperature of -65 °C. The powder simply does not freeze.