Autonomous extinguishing of the furnace PROTOTYPE

March 2018 – chemical fire extinguishing test for furnace extinguishing

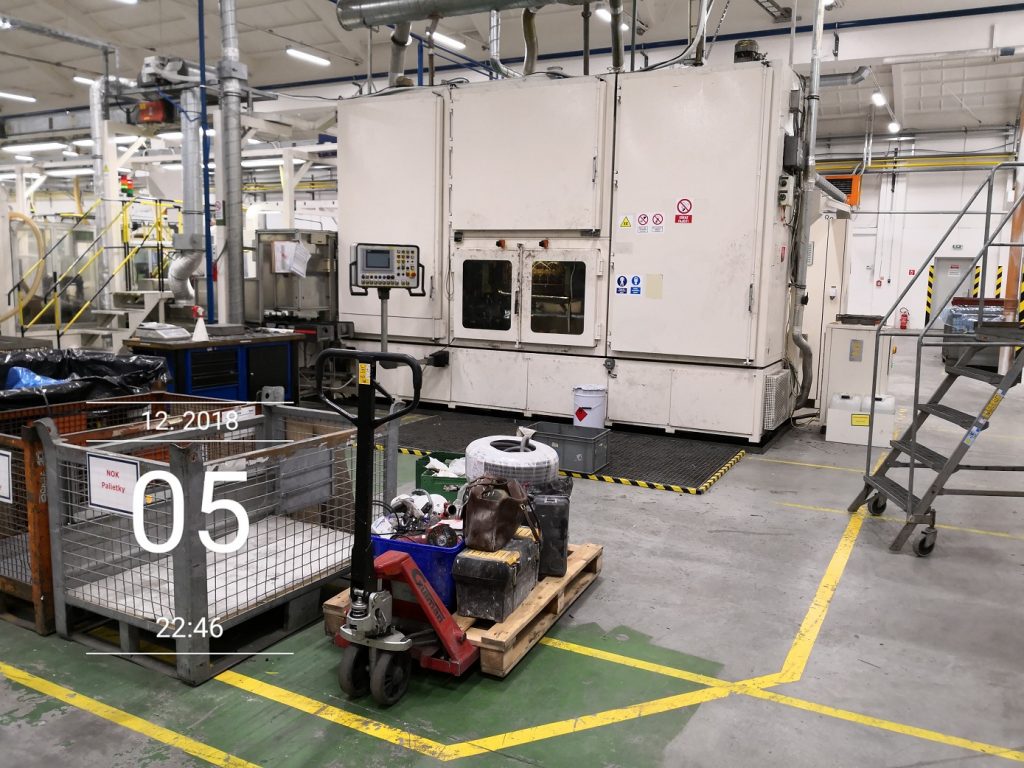

At the beginning of 2018, we were asked by the management of Nidec Global Appliance Slovakia to develop an extinguishing system for two production lines. Specifically, there were two furnaces for wrapping and firing electric rotors (Samsung washing machine motors). The chemical substance that is applied to the rotors is fired in furnaces at a temperature of up to 180 °C. However, if the given temperature is exceeded, the chemical ignites itself and is extremely flammable. The original gas extinguishing of both furnaces was destroyed after a previous fire, which did not extinguish the furnace.

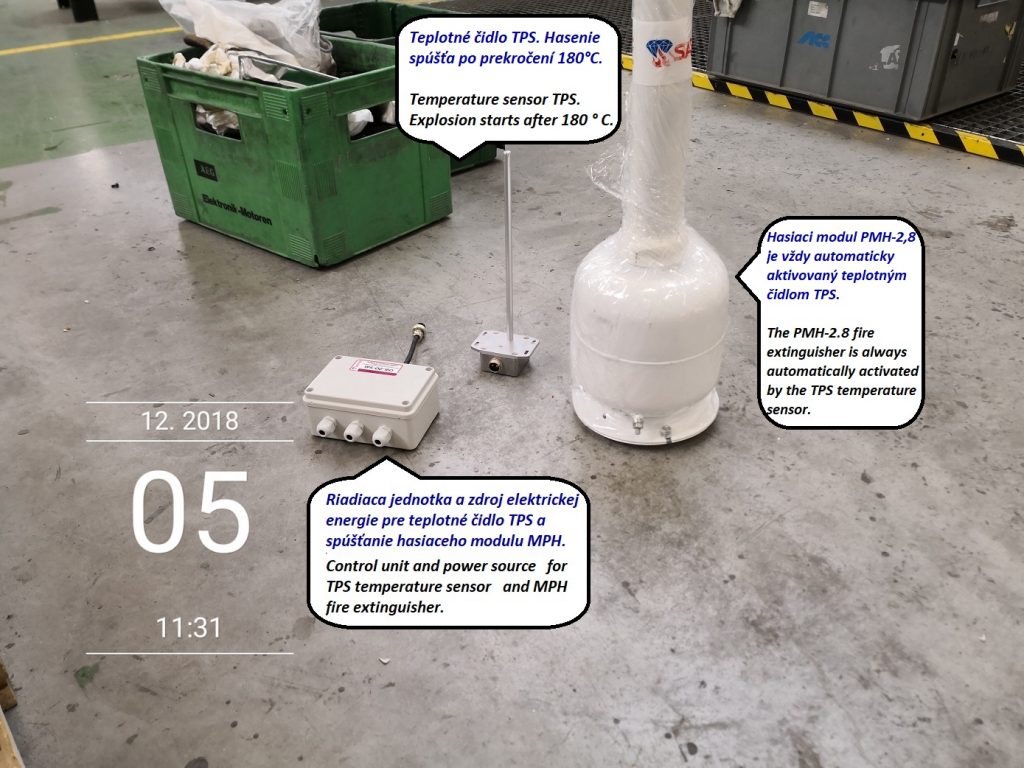

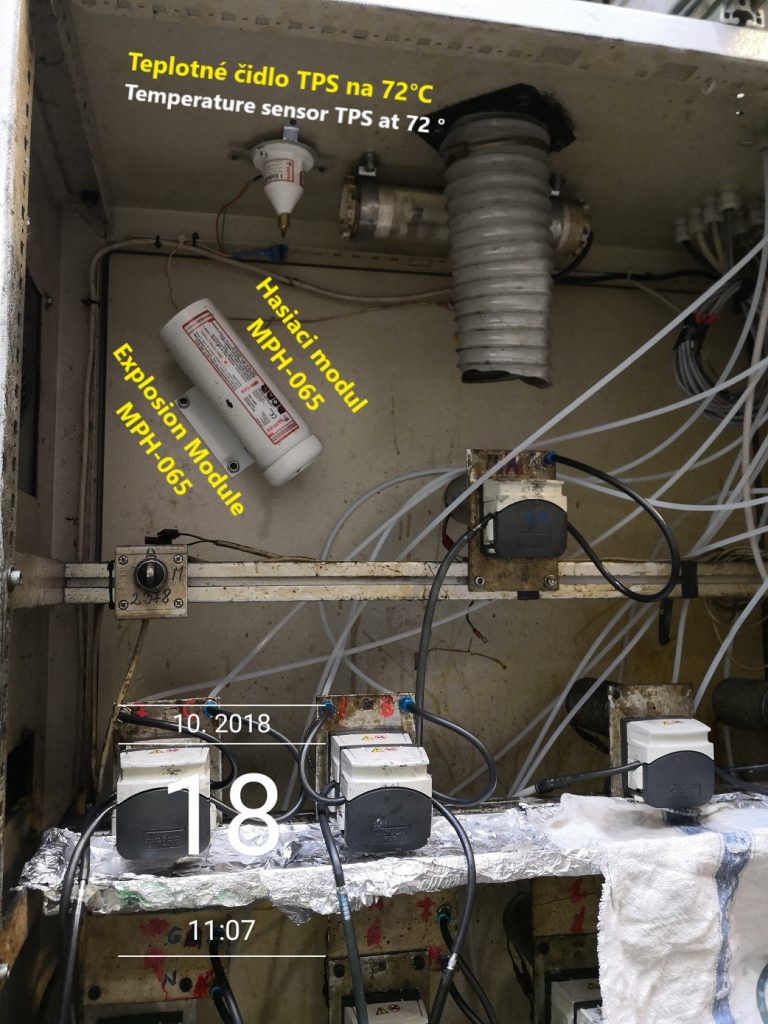

Therefore, they asked us to invent a new extinguishing system that would extinguish and would not damage the furnace. Furthermore, it could be used again. In order to be able to design an extinguishing system, i.e. capacity, we performed an extinguishing test with the smallest extinguishing module MPH-065 + TPS-01-72 (temperature sensor), extinguishing capacity 2.4 m3.

The extinguishing test was successful as expected. After this test, an order was officially placed to develop a fire extinguishing system.

8/23/2018 - The first installation of fire extinguishing on Furnace No. 1 and 2

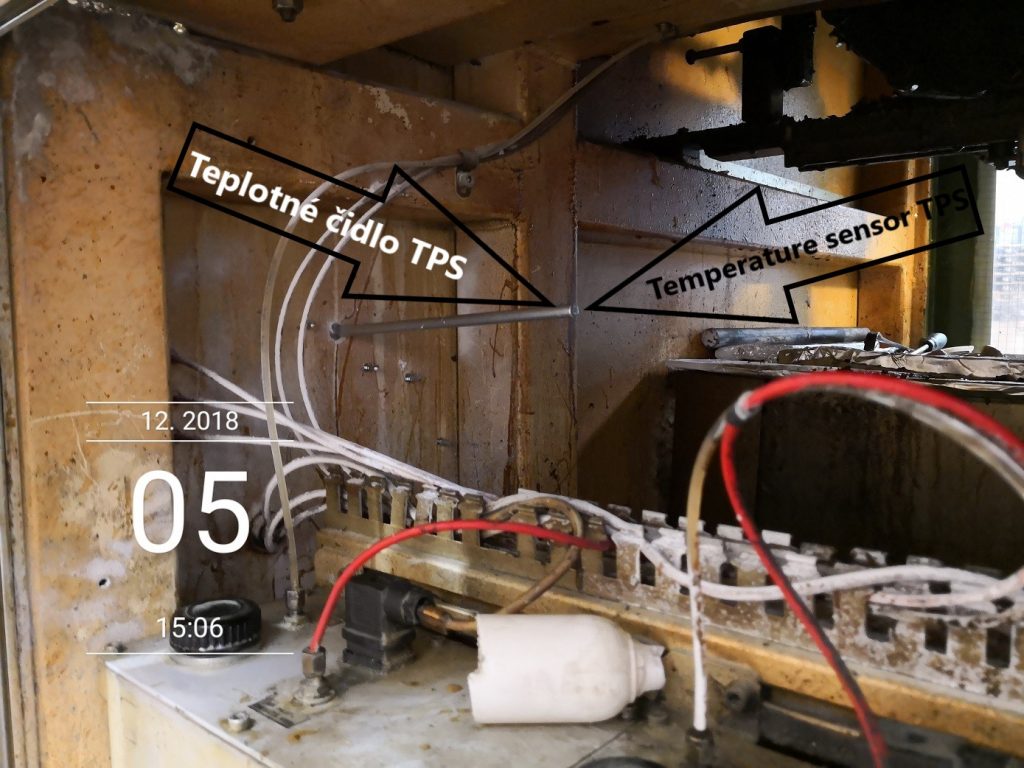

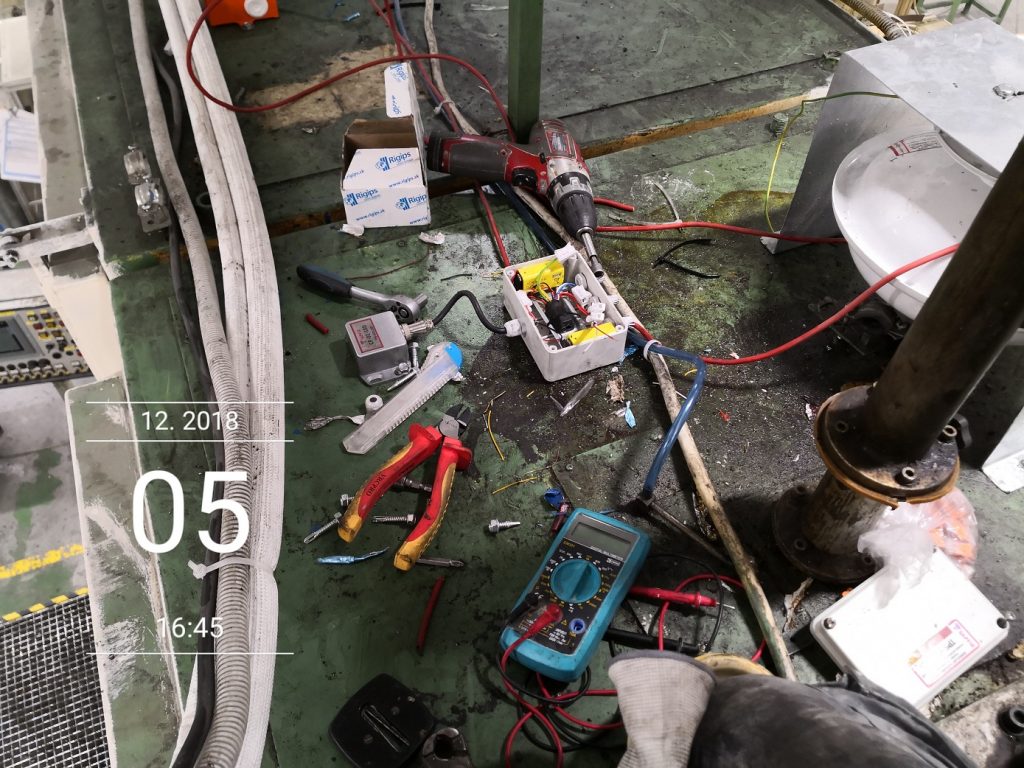

After several months of development and testing of the temperature sensor at 180 °C, the installation of the extinguishing system on Furnace No. 1 and Furnace No. 2 commenced.

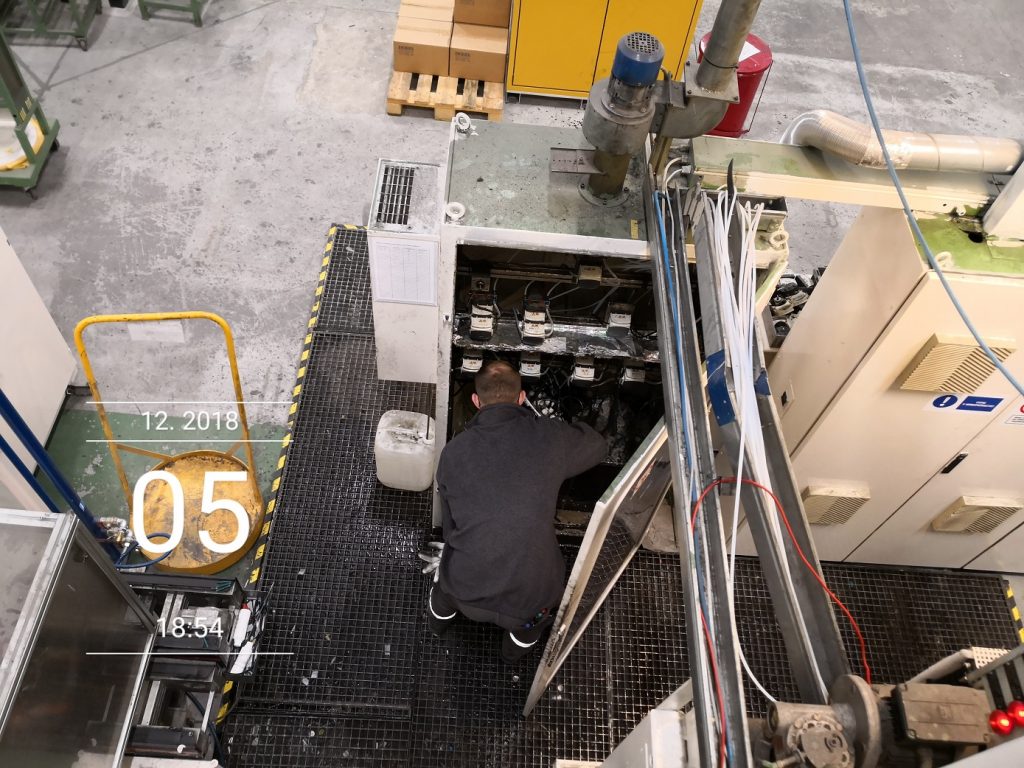

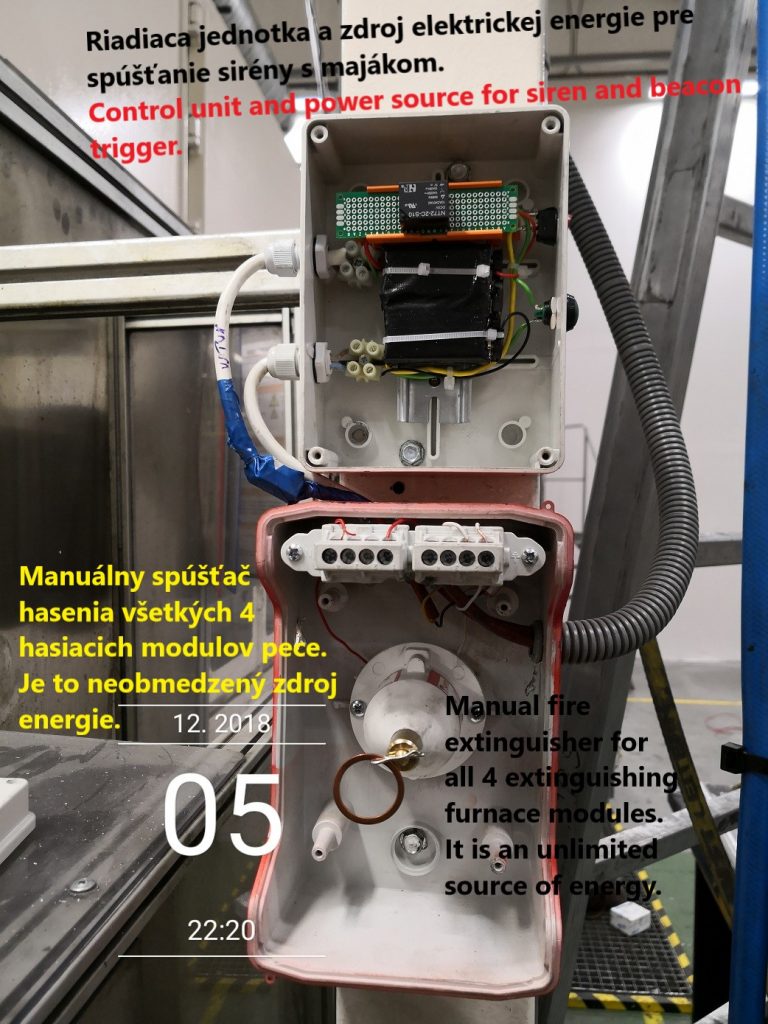

As the temperature sensor at 180 °C had not been invented at that time, we had to invent it ourselves. Therefore, in agreement with the Nidec management, we installed the extinguishing of both furnaces for 3 months with a manual extinguishing trigger. The fire extinguishing systems on the furnace were connected to temperature sensors TPS-01-180, which, however, remained connected only to the alarm. This meant that if the temperature sensor was incorrectly activated during a test run for 3 months, it would only activate the alarm, but the extinguishing itself would have to be started by the furnace operator himself. A manual trigger TPS-01-M was placed on each furnace to activate the extinguishing.

No temperature sensor was activated incorrectly for more than 3 months, therefore the system has shifted to phase 2 = sharp automatic operation.

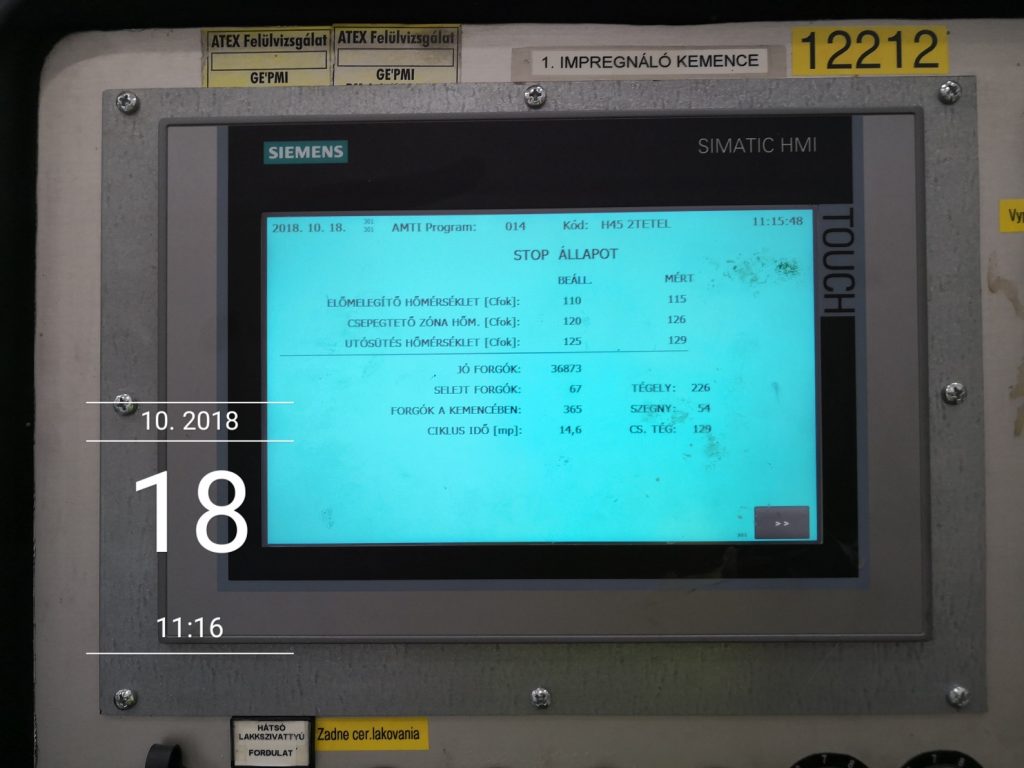

10/18/2018 = Switch to automatic extinguishing

During the development of furnace extinguishing, SAPFIR developed a temperature sensor TPS-01-180 (orange) to activate extinguishing after exceeding the temperature of 180 ° C. During the two-month test operation, these sensors began to be used for the extinguishing of air-cooled locomotive engines (SAPFIR LOCO) and an even improved second-generation temperature sensor TPS-02-180 was developed, which was replaced by the first type of sensor during development. The system switched to automatic extinguishing. When we have already trained the furnace operator, a fire occurred in the lower section of furnace No. 1 and an automatic extinguishing took place. The process was very fast, so the pictures were taken about 1 minute after extinguishing, while the line was switched off, therefore, the extinguished fire of the furnace in real time is visible. The extinguishing itself was provided by the MPH-2.8 extinguishing module with a extinguishing capacity of 65 m3.

According to the factory director (he was there in person), we saved the company over a million Euro. The same price was lost when a fire broke out in the same furnace in Hungary more than a year ago. Since the gas fire suffocated the flame, when they opened the furnace, oxygen was released and the whole furnace exploded, causing burns to the employee. In our case, it was enough to vacuum the powder, replace a few hoses and in 2 hours the furnace was running at full operation. There is beauty in simplicity: STOP-FIRE-SAPFIR

05.12.2018 komplexný test = odovzdanie do ostrej prevádzky. Začatie plynutia 12 rokov garancie funkčnosti systému hasenia. Prototyp sa oficiálne zaradil do segmentu SAPFIR.0