MONDI Štětí a.s. Czech Republic

In 2019, a fire broke out in one of the conveyor towers in SCP MONDI RUŽOMBEROK Slovak Republic. There was a dry pipe on it; a pipe for water extinguishing, which had to be connected to a fire tank first, which pumps water into the dry pipe under high pressure, and only then the conveyor belt can be extinguished. As this process is very time-consuming, until it all happened, the conveyor tower burned down. That’s why Mondi asked us to develop an autonomous fire extinguishing system, without consuming water in order not to damage the electrical wiring that the water damaged.

After inspecting the conveyor tower system, we designed the STOP-FIRE-SAPFIR autonomous fire extinguishing system, which has been maintenance-free for 12 years. Extinguishing works in the temperature range from – 50 to + 50 °C fully automatically without zero electricity consumption, it is cheap and highly efficient.

After designing a comprehensive atomic fire extinguishing system for extinguishing Conveyor towers chips, engine room hydraulic pumps, underground 300m long conveyor and technology, we were asked by the management of Mondi Group to prove the physical functionality of the fire extinguisher. We agreed and we were invited to perform physical extinguishing tests at the Mondi Štětí a.s.

At the request of the Mondi management, we are not allowed to publish the video of the extinguishing test itself (30 euro pallets + 20 l of petrol and 20 l of kerosene), as the test was private for Mondi’s needs. Therefore, similar extinguishing tests are enclosed, which were performed in Greece, Turkey and Slovakia in order to develop the extinguishing of conveyor belts.

MPH-10St cannon extinguishing tests were also performed repeatedly on a hot metal conveyor belt to make sure that the extinguishing system extinguishes any fire of this type. Only then did the actual implementation take place in Mondi. An extinguishing system for 3 towers was installed here.

On 29.7.2020 a fully functional automatic fire extinguishing system was mounted on towers No. 1,2,3 STOP-FIRE-SAPFIR.

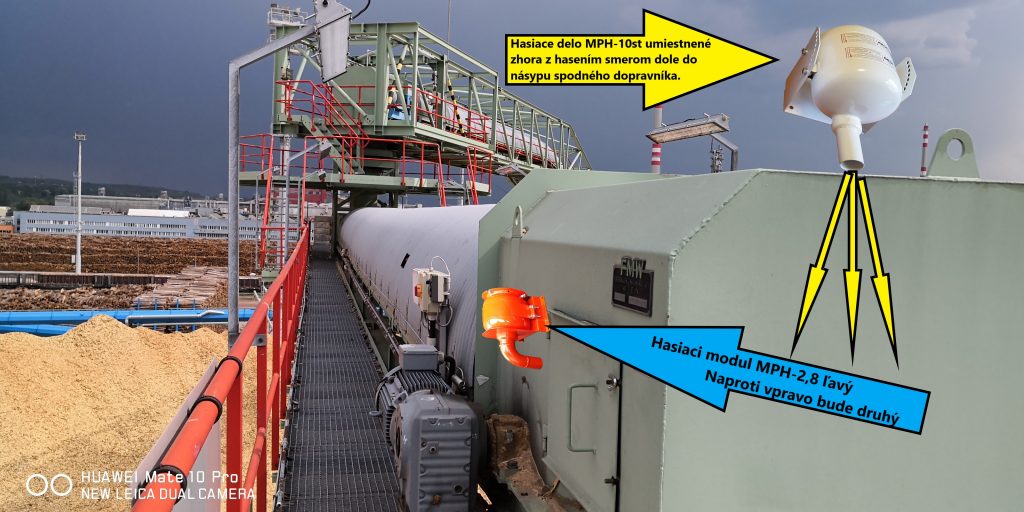

Each conveyor tower consists of a top and a bottom. Therefore, the extinguishing system is divided into two separate extinguishing zones, where the upper part of the extinguishing contains 1x temperature sensor (electric pulse generator) TPS-01TC-72 monitoring the temperature of the upper part of the overflow and the inner part of the conveyor. The temperature sensor supplies 1x MPH-10st fire cannon which extinguishes into the inner part of the overflow + two side fire extinguishing modules MPH-2,8T which provide internal extinguishing between the space of the conveyor belt and its main cylinder, where there is the greatest risk of fire.

If the temperature rises above 72 °C for more than 10 seconds, all 3 fire extinguishing modules are automatically activated and start extinguishing with a total capacity of 370 m3 volume!

The lower part of the chip conveyor tower rotates around its own axis indefinitely and therefore it was not possible to connect the upper part of the extinguishing part to the lower part by a cable. The upper conveyor pours over the chip overflow to the lower conveyor, which then transports it for emptying. However, right at the overflows and the end main conveyor rollers, massive deposits of wood dust, wood sawdust and wood chips are formed in combination with Vaseline and oil from the bearings of the conveyor rollers. In summer high temperatures, it acts as a time bomb for self-ignition by friction. Therefore, the lower section is equipped with its own temperature sensor TPS-01TC-72 + fire extinguisher MPH-10st with a total capacity of 240 m3 of extinguishing, and the top extinguishing itself will ensure high efficiency. The total capacity of the upper and lower extinguishing is a total of: 610 m3 of volume.

The original design of the extinguishing system was to be connected by a cable line to the control room and their EPS alarm system. However, due to technical complications, high cost and technical complexity (kilometers of cables), Mondi management asked us to invent our own EPS alarm system.

For the needs of Mondi, we offered a GSM alarm via SMS to a mobile phone. Such a technical solution is often used for clients in Germany (industry). In the course of 2 weeks, we physically prepared a technical solution, which, after approval by the Mondi headquarters, was installed on 12/07/2020 on all fire extinguishing zones of the chip conveyor towers.

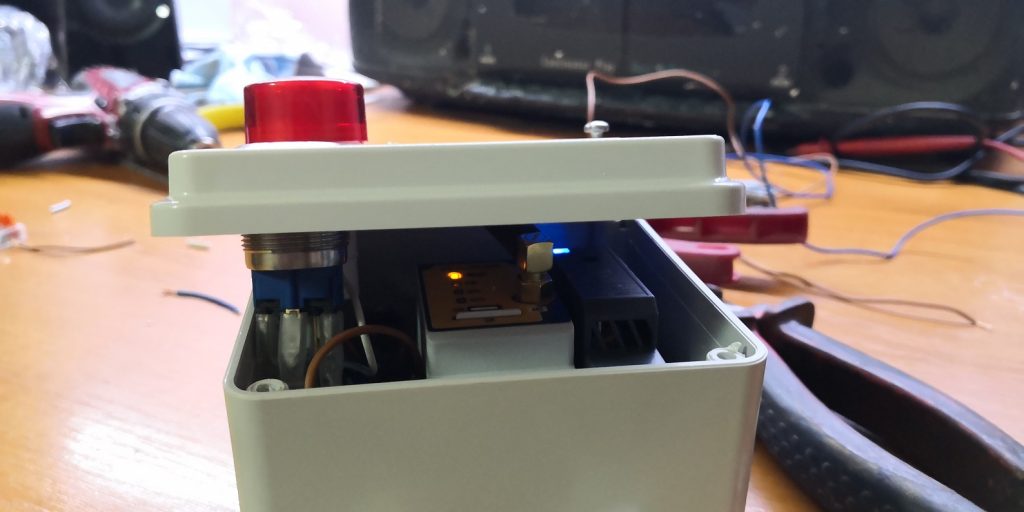

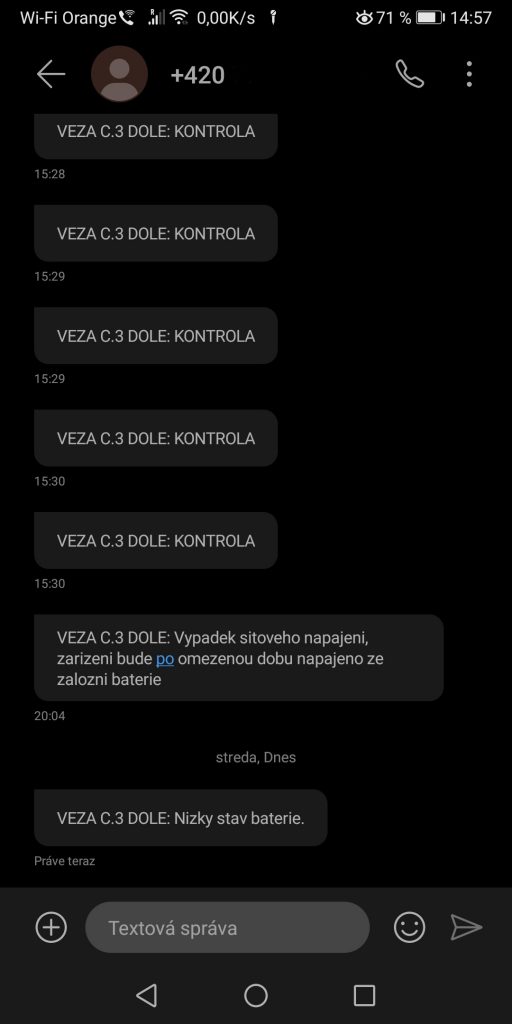

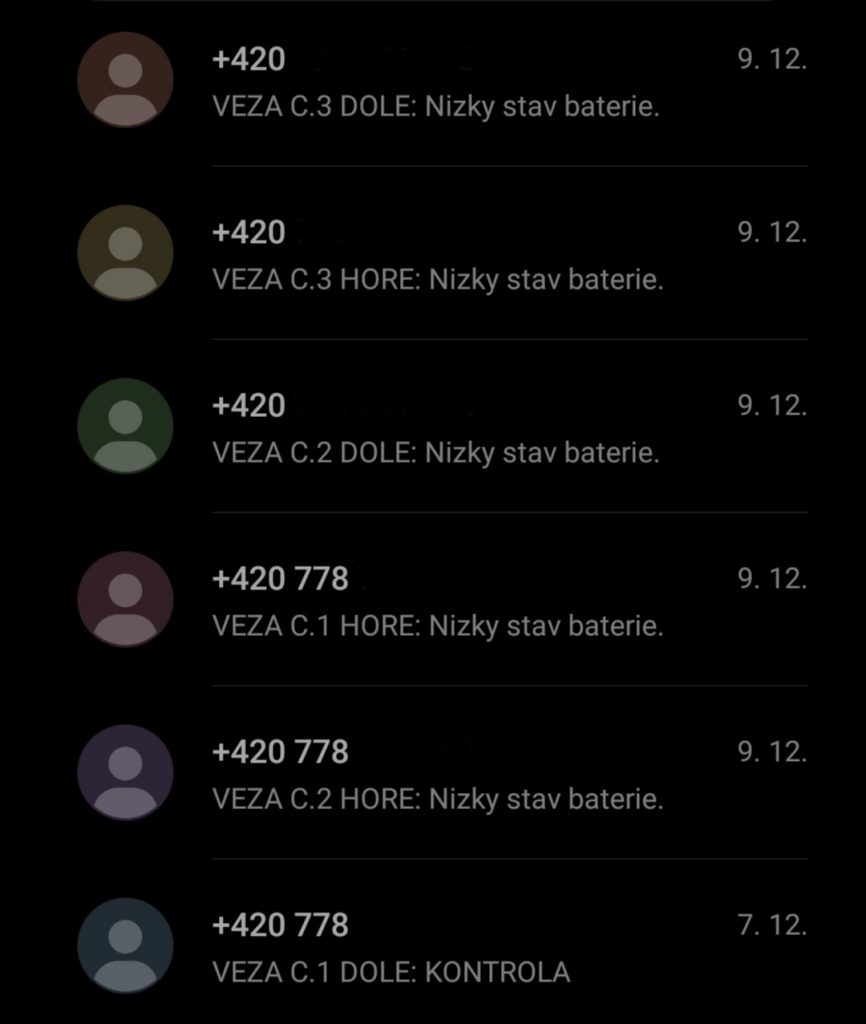

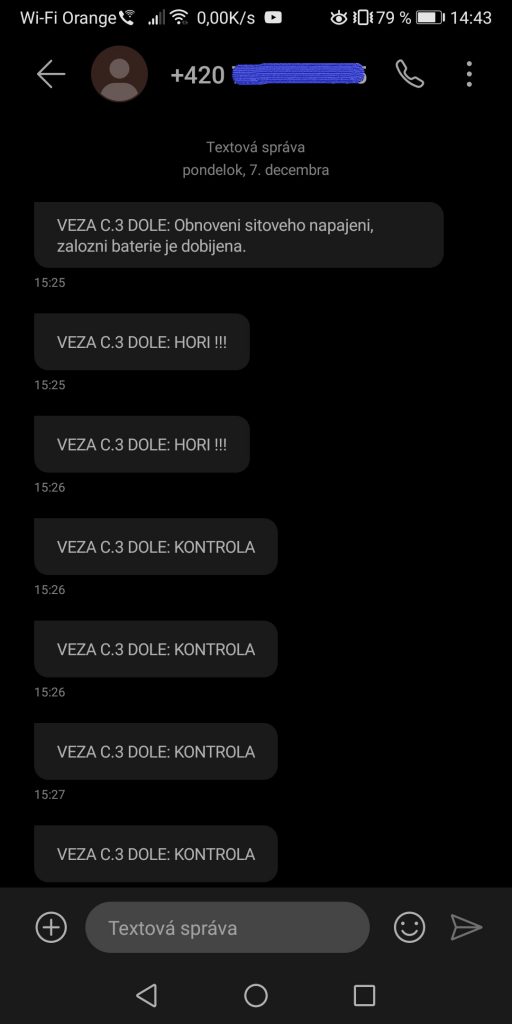

The GSM module can receive and send an SMS message. We designed the highest level of wireless GSM EPS alarm with a functional analog keyboard equipped with 6 trigger light buttons with its own mini beacon. If the automatic extinguishing failed due to a technical fault, the operator in the control room would manually start the extinguishing of the given section by pressing the button on the wireless keypad remotely. However, as the existing EPS system administrator in Mondi (total alarm and camera system) could not react flexibly to our extremely cheap GSM alarm technology, in agreement with the Mondi management, we proceeded with the basic reporting system for GSM modules, where a GSM module was connected to each fire extinguishing zone, which performs real-time diagnostics of the state of the fire extinguishing system. If there is an automatic extinguishing, it sends an alarm sms to 6 mobile numbers (5 Mondi and 1 Sapfir technician). The GSM module is connected to a stable 230 V AC power supply. If there is a power failure, it switches to its own power supply of energy where it can continue to operate for a maximum of 40 hours. This is enough time to send information sms in case of discharging the power supply of the GSM module, if the electricity (power supply) has not been restored.

After installing the GSM module, physical tests of the current state of the extinguishing system were performed in real time, plus a manually simulated extinguishing process. Each temperature sensor has its own diagnostic magnetic line with which the technician can perform a system function test during a service check. Therefore, in real time, alarm sms about a fire break-out came in a given section of fire in real time.