SAPFIR LOCO prototype for rail grinder extinguishing

Year 2018 = extinguishing Plasser & Theurer SSP110SW

After the successful design of a rail machine – plow locomotive extinguishing system, we were asked to invent an equally efficient and inexpensive automatic extinguishing system.

A specific requirement was to devise an automatic rail grinder extinguishing system, namely extinguishing for hydraulic grinding heads and hoses. A few years ago, a specific grinder burned down and its renovation cost about 2 years of reconstruction and about € 3.5 million.

As TSS GRADE and Hrochostroj cooperate, we were recommended by the TSS management to invent fire extinguishing systems in addition to the grinder for other types of locomotives and rail machines, which happened over the course of several months and years. With the original first prototype SAPFIR LOCO for TSS, completely new autonomous fire extinguishing systems SAPFIR LOCO have been developed. And the development is moving further and further…

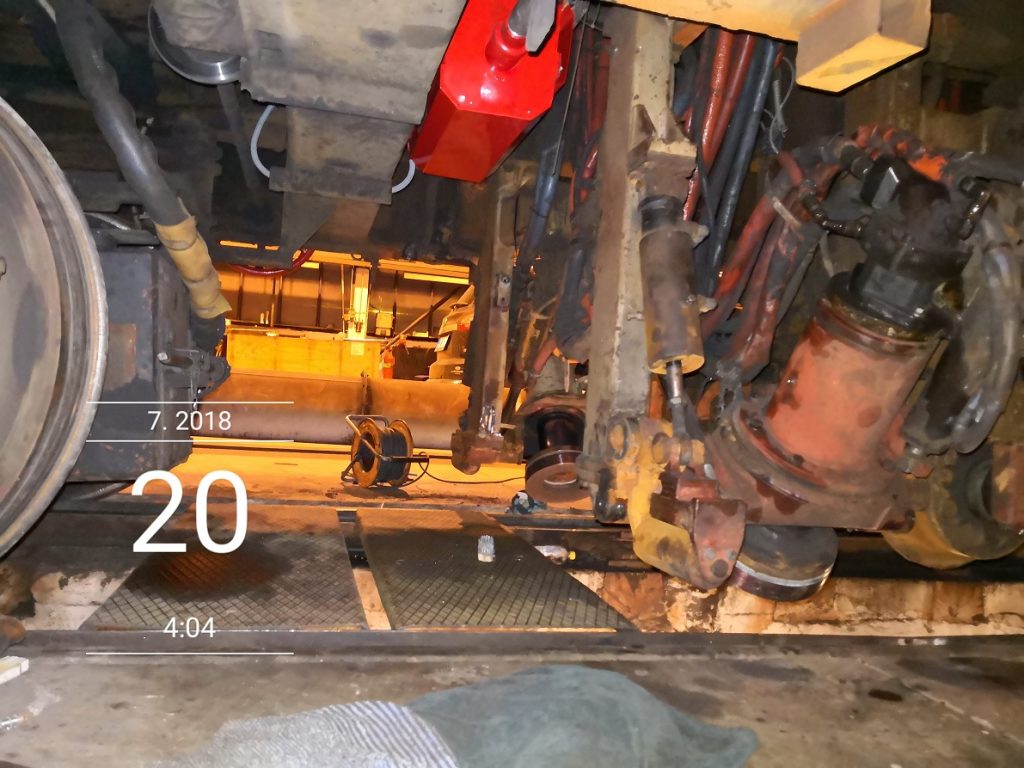

Year 2018 = Assembly of the SAPFIR LOCO Grinder PROTOTYPE

On July 20, 2018, the Hrochostroj depot carried out the installation of a prototype for extinguishing grinding heads and hydraulic cable duct.

The original comprehensive design of extinguishing both wagons (locomotive with grinder) and the extinguishing wagon itself (water tank) was limited only to extinguishing the rail grinding technology itself.

The grinder extinguishing system consists of two large-capacity parts 2x MPH-24T with a total extinguishing capacity of 500 m3. As the grinding heads themselves are heated to a temperature of 900 – 1000 °C, we had to place the fire extinguishers away from the radiant heat. The distribution of the extinguishing powder is ensured by pipes with directional chips on the grinding heads and hydraulic distribution hoses. Grinder extinguishing is done only with a manual extinguishing trigger MPH-01-M. Extinguishing is only possible by operating the locomotive.

In the upper part above the grinder there is a cable channel where the hydraulic distributions and cables are placed. To prevent a fire in this interior, an APPS MPH-5T automatic fire extinguishing system with a TPS-01TC-110 temperature sensor was installed in the center of the duct. If the temperature in the cable duct exceeds 110 °C, an automatic extinguishing with a capacity of 100 m3 starts. Capacitively, it covers the volume of the channel three times.

The extinguishing system was installed and fully functional with a 12-year life guarantee in an environment from -50 to + 50 °C. A functionality check service is performed every 6 months.

Extinguishing demonstration MPH-5T

Extinguishing demonstration MPH-24T

05/07/2019 Replacement of fire extinguishing parts after extinguishing the fire of the grinding part of the locomotive.

At the end of April 2019, during the grinding of the rails, one of the hydraulic hoses cracked, which caused a massive fire in the locomotive. Fortunately, the crew was prompt and immediately activated the chassis fire – SAPFIR LOCO. The fire was immediately extinguished.

After replacing the cracked hydraulic hose and making a minor repair, the set continued to grind the rails as planned. Subsequently, the incident was reported and a few days later, an inspection was performed by SAPFIR technicians to determine the condition of the locomotive’s fire extinguishing system.

After the inspection, it was clear that only the emptying of fire extinguishers 2x MPH-24T was damaged. The power lines themselves, protectors and chips were not damaged by the fire.

During the planned maintenance service at the Hrochstroj depot, the fire extinguishers themselves were replaced and the system was restored to 100% functional condition.

The APPS MPH-5TC automatic fire extinguishing system in the cable duct remained intact. There was no extinguishing, as the temperature did not exceed 110 °C since the lower extinguishing put out the fire right at the beginning. The system remained original without the need for replacement and fully functional.